Printed Circuit Board

IHARA will address your development challenges with advanced technology.

The demand for increased capacity and speed in electronic information transmission requires high-layering, high-density printed circuit boards, as well as improvements in heat resistance, electrical characteristics, and reliability. IHARA's technology aims to stay one step ahead in meeting your demands for printed wiring boards through our relentless challenges.

- Proper data correction for manufacturing conditions

- Impedance simulation

- High-layer formation

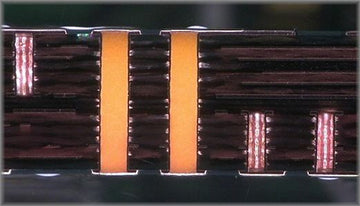

- IVH, BVH

- Evaluation of characteristics and reliability

- Selection of appropriate materials

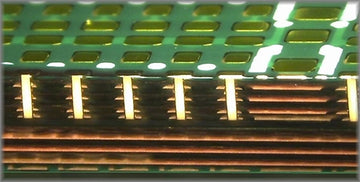

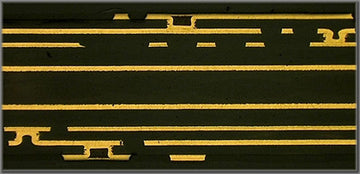

- Fine pattern formation

- Build-up

Materials

Please inquire about material stock availability.

- Each low-inductance materials (MEGTRON4, MEGTRON6, MEGTRON7, Low-dielectric PPE, Teflon, etc.)

- High TgFR-4

- High thermal conductivity materials

- Low thermal expansion FR-4

Handled Product Lineup

- Single-sided and double-sided boards

- Multi-layer boards

- Build-up boards

- IVH and BVH boards

- Flexible boards

- Impedance-controlled boards

- High-frequency compatible boards

- High-current boards

- Metal bars and metal core boards

- Various simulation designs

Have questions?

Solving problems is what we live for. Reach out — even if you’re not

sure what your next step is. You’ll hear back from an expert today.

PCB design

Board design is the key to improving board quality. Ihara Denshi Kogyo provides design solutions that take into account

substrate characteristics and manufacturing rules, utilising its strengths as a substrate manufacturer.

We are also actively involved in cutting-edge technology to meet all customer needs.

(Participation in the JPCA DDR4 demonstration project, 2016)

PCB design overview

Supports a wide variety of CAD systems, including Zuken's CADVANCE-α III.

Designs specified by the CAD system are also supported.

・Single-sided substrates to 20-layer high multilayer substrates

・Build-up and IVH substrates

・High-current substrates

・Hetero-sided substrates

・Characteristic impedance control boards

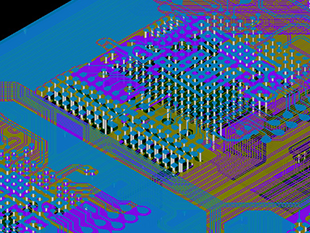

・SI/EMC simulation design

・Flexible substrates

・Other boards

A wide variety of board designs can be handled.

We can also handle Gerber data and design changes from the actual board.

Please feel free to contact us.

Design achievements

・High-speed interfaces (PCI Express, DDR4, etc.)

・Communication equipment (control boards, I/O boards)

・Automotive (air-conditioning, navigation, meter panel boards, car audio)

・Aerospace (peripheral equipment)

・FA (vending machines)

・Medical equipment (blood concentration measurement)

・Measuring instruments (colour difference meters, densitometers, water quality meters, flow meters, radiation dosimeters)

・Amusement (power supplies, images, electric decorations, sound, payouts, launches, control boards)

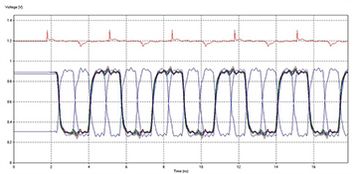

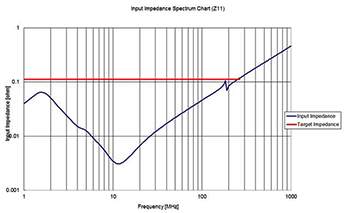

Simulation Design

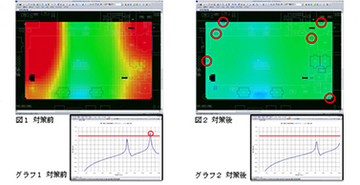

The increasing speed and low voltage of devices has led to a reduction in noise margins becoming an increasingly apparent problem.

By carrying out various simulations at the design stage and implementing countermeasures, we can help you reduce the number of prototype production runs,

shorten development times and reduce development costs.

Depending on your budget, we can provide various combinations, such as pre-simulation only, EMC simulation only, etc.

- SI Simulation

- PI Simulation

- EMI Simulation

Have questions?

Solving problems is what we live for. Reach out — even if you’re not

sure what your next step is. You’ll hear back from an expert today.